Lesson Learned in Pressure Decay Testing of a BSL-4 Laboratory

Phillip Stanford / March 29, 2019

WorkingBuildings was recently engaged to perform annual performance verification testing on a BSL-4 laboratory. One of the critical aspects of initial and annual performance verification in BSL-3Ag and BSL-4 facilities is execution of a pressure decay test on the envelope of the containment suite. This pressure decay testing involves sealing the supply and exhaust air inlets to the room, and pressurizing the space to greater than 2.0 in. H2O relative to the surrounding spaces. This creates a stagnant, sealed volume of air inside the containment suite. The space pressure is allowed to decay over the course of 20 minutes to quantify the leakage of the overall containment boundary. The test results are passing if the final space pressure exceeds 50% of the initial test pressure after 20 minutes.

It is well known that changes in temperature during a pressure decay test will skew the data. This is based on the ideal gas law which states that the pressure of a sealed volume of an ideal gas will vary with a directly with the average temperature of the gas. To combat this effectively , we always turn off all lights and heat generating equipment several hours before the test to make sure the space temperature is as stable as possible for the 20-minute test.

In this recent engagement, the researchers at the institution required that two -80º C freezers inside the main isolation room remain in the space and operational during the annual performance testing. To combat the anticipated heat gain anticipated from the freezers, WB setup several temperature data loggers throughout the space to enable us to correct the pressure data for any drift in the average room temperature during the test.

As we attempted the pressure decay testing, we came across an unexplained phenomenon. The data was sporadic and non-repeatable. On some attempts, we would see rapid pressure changes at the start of the test, but on others, we would see promising results for 10 minutes or more, and then a rapid dip in pressure toward the end. Throughout all of these attempts, the average room temperature remained virtually unchanged.

After numerous failed attempts, and tirelessly looking for breaches in the containment envelope, we looked back over several hours of pressure data, and realized that there was a repeated pattern of pressure spikes and dips being observed on a cyclical pattern. Finally, we realized that this pattern seemed to match the cycle times of the -80ºC freezer compressors. We had been aware of the potential for the freezers to increase the overall room temperature, and thus the room pressure. What we had not realized was that the freezers create a pressure wave that propagates nearly instantaneously (at the speed of sound) throughout the sealed room. The localized heat output from the freezers’ condenser vent causes rapid expansion of the immediately surrounding air. This expansion creates the pressure wave, which propagates through the entire sealed room.

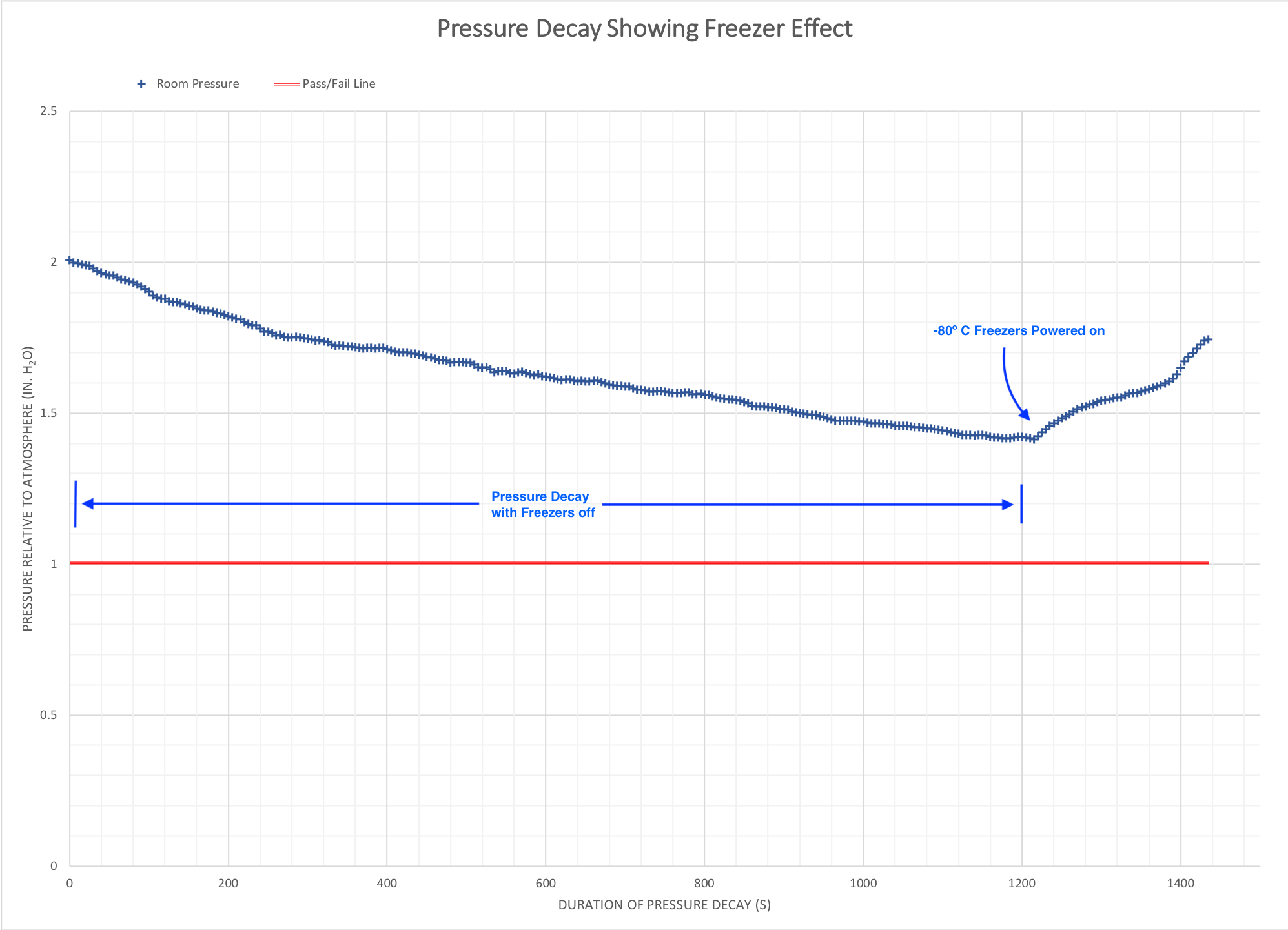

For confirmation, we explained our theory to the researchers, and gained permission to shut down the freezers for the duration of the 20-minute test. We found that the pressure decay suddenly followed a smooth curve, and yielded passing results. Immediately following the 20-minute mark, we energized the freezers and the pressure (see chart below).

As the chart illustrates, the freezer pressure wave actually impacts room pressure rate of change significantly more than the leakage of the containment envelope. The pressure wave from the freezers causes the room to actually regain 50% of the decayed test pressure in just over three minutes.

This experience made a major addition to our ever-expanding library of lessons learned in high containment facilities, and sheds even more light on the challenges of controlling and operating complex BSL-3Ag and BSL-4 laboratories.